Construction sites contain various hazards ranging from the kind that can cause minor harm to workers right up to their death. Some are obvious and easy to spot, while others are less so and require training to recognize. A hazard is usually identified and reported in one of three ways:

- By the Jobsite Foreman during a routine Hazard Analysis before starting work each day.

- By an individual worker who spots an unsafe situation while completing their specific task.

- By a Supervisor during a jobsite inspection.

Once a hazard is identified, it must be controlled appropriately to keep workers safe from it. The most effective way to do that is through a corrective action.

What is a Corrective Action?

A corrective action is a six-step process designed to formally identify, control, and document job site hazards. The components are:

1. Hazard Identification

Identification is the most crucial step in the entire process; without it, the hazard is left uncontrolled and your workers at risk. Failing to identify or neglecting to report a job site hazard is one of the root causes of injuries.

Workers require training to recognize hazards specific to their trade and their job site. Hazards change over time, as work continues, tools wear and other trades become involved. Their identification is an ongoing process and requires frequent consideration.

Additionally, upper levels of management need to be involved in the process, including foremen, supervisors and safety directors, in more formal capacities such as job site inspections.

2. Severity

Once a hazard is identified, it needs to be assigned a severity level, most commonly:

- Low: small risk of occurrence resulting in minor injuries

- Medium: occurrence is more likely, and injury could result in lost time

- High: likely to occur and if so, would be a potentially life-threatening situation

Defining the level of severity for each hazard helps provide others with a proper sense of urgency. A high severity level should result in work stopping, at least in the directly affected areas, until the hazard is controlled.

A low severity could wait until the next available worker can complete it, but there is less risk, so that is alright. Medium severity should be given more priority than low but doesn’t require a stop-work order.

3. Category

Although assigning a category isn’t vital to the corrective action process, it holds many long-term and bigger-picture benefits. Once you begin tracking categories, you will be able to analyze them to find patterns and trends. The most frequently cited categories will signal where your problem areas lie and allow you to focus your training where it is needed most.

To get started, you need to determine a list of categories your trade encounters and then label each corrective action with the most appropriate type. Some commonly used categories are:

- Compressed Gas

- Confined Space

- Documentation

- Electrical

- Fall Protection

- First Aid

- Housekeeping

- Hot Work / Fire Prevention

- Ladders

- Machines

- PPE

- Tools

- Trenching

- Vehicles

4. Recommended Control

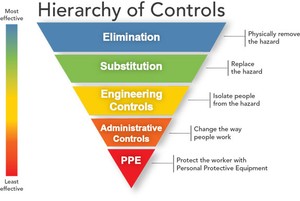

The control is the action required to make the job site safe for your workers. The best control is eliminating the hazard entirely, but that is not always possible on a construction site. Therefore, a decision needs to be made as to the next highest level of protection.

We recommend using NIOSH’s Heircharcy of Controls (pictured below) to select the most feasible and effective option.

The selected control also needs to be very specific so that it is properly completed. For example, if there is an open hole in a floor, you need to say more than “protect the hole.” You could request a railing is built around it, or that it is covered with a piece of plywood and marked ‘Hole.’

These decisions should be made by someone with more safety training than a standard tradesperson, such as a foreman, supervisor, or safety director.

5. Assigned to

In addition to being specific about the control, you also need to assign a particular person to action it. When the owner of the control is made clear, there is a much better chance it gets completed.

For example, when you say something such as “Someone, cover that hole,” it’s possible the crew will each assume someone else is doing it. You should also be clear with the person you assign that you expect them to do the work and not pass it on to someone else.

6. Follow Up

Every corrective action needs to be followed up on to ensure its completion. Sometimes this happens at a later time, but it’s also possible soon after the hazard is identified.

For example, if the hole in the floor gets covered and marked before leaving the job site, you can update the status of the corrective action to ‘complete.’ However, if you opted for a railing and it won’t be complete until the end of the day, the status remains as ‘open’ until it is confirmed as complete.

The follow-up should always be done by someone in a leadership role, not the person assigned to complete it so that it is verified as complete and correct.

How to Use Corrective Actions Effectively

When hazards are managed proactively through formal corrective actions, the number of work-related injuries and illnesses is drastically reduced. However, it will take the efforts of your entire construction team to be successful at this.

Everyone will need to do their part, and that means from the top of the company down. If your company culture is to prioritize production over safety, this program simply will not work.

In order to increase your chances of success when using corrective actions, we suggest you implement the ideas in this article: Top 5 Ways to Foster a Safety Culture in Your Construction Business

Share Article

Keep on current news in the construction industry. Subscribe to free eNews!