Construction sites are dynamic environments. Effective construction safety management and compliance form the bedrock of successful project execution.

OSHA regulations exist to protect workers. They make sure businesses operate within legal boundaries.

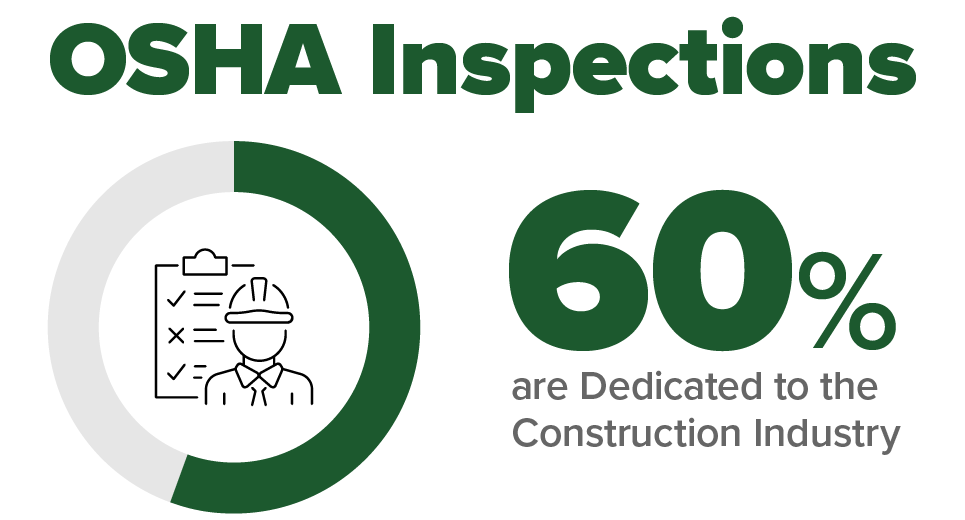

Construction consistently ranks among the most hazardous industries. In fact, nearly one in five deaths among workers in the United States happens in the construction industry. It’s also why 60% of OSHA inspections are dedicated to the construction industry.

It also sees many OSHA violations, which carry potential fines in the thousands. That’s why maintaining rigorous safety standards is fundamental to operational success.

The complexity of modern construction projects, combined with tight deadlines and budget constraints, can make safety compliance seem daunting.

Understanding and implementing OSHA requirements is an essential investment. It protects construction workers, contractors and the whole business.

There are key aspects of OSHA compliance in construction. Learning practical strategies for maintaining safe and compliant job sites will help avoid complications, accidents and OSHA violations in the future.

Key Takeaways

- Training: Have workers take regular training programs that cover:

- Fall protection

- Scaffold safety

- Equipment operation

- Hazard communication

- Documentation:

- Create site-specific safety plans

- Maintain equipment inspection records

- Track PPE management

- Regular Monitoring:

- Conduct weekly safety audits

- Rotate supervisor inspection duties

- Require 24-hour resolution for safety issues

- Active Communication

- Hold daily Toolbox Talks

- Maintain clear emergency protocols

- Make sure all trades take part in regular safety meetings

- Technology Integration: Use safety management software to:

- Centralize documentation

- Track certifications

- Enable quick OSHA compliance reporting

Tip 1: Put in Place a Comprehensive Training Program

Training is the foundation of workplace safety in construction. It extends far beyond new-guy safety training.

Construction site safety training demands a methodical, comprehensive approach. Proper training needs to address every OSHA regulation that relates to daily operations.

Construction site safety training demands a methodical, comprehensive approach. Training needs to go over every OSHA regulation that relates to daily operations.

This means contractors should develop structured programs that cover more than the basics. This includes:

- Fall protection

- Scaffold safety

- Proper equipment operation

- Hazard communication

The key is to make training sessions regular events rather than one-time events. Ongoing training sessions allow workers to build their safety knowledge over time.

To be effective, training programs should incorporate hands-on demonstrations, real-world scenarios, and interactive elements. These elements help workers keep and apply safety concepts.

The most successful training programs also have knowledge benchmarks. Benchmarks ensure that workers attend training lessons. They also help managers make sure workers master the safety concepts presented.

Regular tests help verify that safety knowledge translates into proper workplace behavior. This creates a workplace culture where safety is important rather than an afterthought.

Tip 2: Create a Site-Specific Safety Plan

A site-specific safety plan creates real-life protocols specific to each project’s unique challenges. These plans must address construction site hazards like:

- Adjacent structures

- Soil conditions

- Overhead power lines

- Confined spaces that workers may encounter

Safety plans must include emergency response procedures, evacuation routes and locations of first-aid stations. This part of the safety plan can mean the difference between life and death for an injured worker.

Every safety plan should have jobsite customization. It should detail specific safety measures for different project phases. It should also identify potential risks of completing work in each trade.

Regular site checks ensure the safety plan stays relevant as work gets done. When new subcontractors arrive or project phases change, contractors need to immediately review and update the safety plan to address the changes. This proactive approach helps prevent accidents.

The plan should also establish clear lines of communication and responsibility. It needs to define who has the authority to change safety protocols. It also needs a checklist of how to keep workers updated while on-site. This becomes especially important during emergencies or when there is a new hazard.

Tip 3: Maintain Rigorous Equipment Inspection Protocols

Equipment inspection protocols impact worker safety and project efficiency. Daily inspection checklists should cover key components like:

- Structural integrity

- Electrical systems

- Safety mechanisms

These checks must occur before equipment operation begins each day.

Contractors need to document inspections. This includes tracking inspection dates, findings and corrective actions.

After finding a defect in equipment, safety managers need to immediately tag and remove the heavy equipment. This prevents accidents.

Repair records should detail the issue and repair date. It should also show that someone verified the equipment as safe before returning it to service.

Personal Protection Equipment (PPE) management demands equal rigor. Contractors should track service life dates for all PPE items.

Create a replacement schedule based on manufacturer guidelines and actual wear conditions. This will ensure that protective gear maintains effectiveness throughout use.

Tip 4: Schedule Regular Safety Audits and Inspections

Regular safety audits serve as a proactive defense against workplace hazards.

Weekly inspections should examine all aspects of site safety. This includes scaffolding integrity and proper PPE usage. Audits must follow detailed checklists aligned with current OSHA standards.

Consider rotating audit duties among supervisors. This way, contractors can prevent oversight blind spots or “going through the motions” of safety evaluations.

Each identified issue requires immediate attention. Each will need a 24-hour resolution window ensuring swift action.

The audit process should create documents detailing:

- Findings

- Corrective actions taken

- Verification of completed repairs.

This creates proof of safety compliance efforts. It also highlights areas that need more resources.

Tip 5: Invest in Proper PPE and Protection Materials

Quality safety equipment is a necessary investment in worker protection. The initial cost of premium PPE and safety systems is minimal compared to the potential costs of workplace accidents or OSHA violations.

Key focus areas include:

- Fall protection harnesses

- Anchor points

- Respirators

- Scaffold components

All protective equipment should have proven safety records and proper certifications.

Regular inspections and timely replacement of safety gear and worn equipment are a must. They make sure the protective measures are still effective.

Tip 6: Establish Clear Communication Protocols

Effective safety communication requires reinforcement.

Daily toolbox talks, safety boards, and written notices help share information. They make sure all workers understand the information, no matter how they learn best. Contractors need to display emergency protocols and contact information and update them regularly.

Safety meetings should include workers from all trades to discuss hazards.

Essential protocols include:

- Daily safety briefings

- Hazard notification systems

- Emergency response procedures

Visual aids like safety signage, color-coded warning signs and site maps reinforce communications. It also helps bridge potential language gaps.

Tip 7: Stay Current With OSHA Standards

Staying current with OSHA regulations requires dedicated attention and clear accountability.

Consider assigning responsibility for monitoring OSHA updates to a specific team member. Choose someone who reviews regulatory changes monthly. This person should look at how new standards affect current practices and develop plans for necessary changes.

Key monitoring tasks include:

- Reviewing OSHA’s newsletter subscriptions

- Following industry association updates

- Attending relevant safety conferences or webinars

When changes occur, communicate updates to the team and change relevant training materials.

Tip 8: Build Strong Relationships With Subcontractors

As a contractor, you are responsible for workplace safety. This is true even when working with subcontractors on shared jobsites.

You have a legal and ethical obligation to make sure all work happens in a safe environment no matter who is completing the job.

Strong subcontractor safety management requires clear expectations and consistent oversight. You should outline all safety requirements in subcontractor agreements. This includes:

- Specific protocols

- PPE standards

- Participation requirements in construction safety programs

Regular meetings can address potential conflicts between subcontractors.

Communication helps make sure everyone understands their safety responsibilities. These meetings should cover upcoming work phases, shared workspace coordination and resolution of any safety concerns.

Documentation of subcontractor safety incidents helps maintain accountability. It also helps identify areas that need improvement.

Tip 9: Use Software to Keep Safety Data Close

Construction safety laws demand an organized, systematic approach to tracking countless moving parts.

Safety software serves as a centralized digital hub. It transforms what was once a maze of paperwork into a streamlined, accessible system.

The real power of safety management software lies in its ability to multitask between different aspects of job site safety. This helps prevent safety issues from falling through the cracks.

The software’s predictive capabilities also enhance proactive safety management. These systems can identify potential safety risks before they lead to accidents by analyzing reports and data.

Beyond basic record-keeping, modern safety software often includes features for:

- Scheduling regular inspections

- Managing training certifications

- Generating compliance reports

Imagine: The next time OSHA requests to see documentation, you can retrieve all necessary records with a few clicks.

Taking a digital approach to safety management improves compliance. Safety software promotes a more responsive, data-driven safety culture. Contractors can identify potential hazards and address them as they happen.

Upgrade Workplace Safety With SafetyHQ®

Construction safety management is a major challenge. After all, it is one of the most hazardous industries. The construction site safety tips listed above can help you develop best safety practices and create a safer work environment.

OSHA regulations keep workers safe and ensure legal compliance. Despite this, construction continues to see many violations.

Safety compliance on the jobsite is particularly challenging. Yet, following OSHA requirements is still important for protecting workers, contractors and businesses.

Key strategies for maintaining OSHA compliance include:

- Comprehensive training programs

- Site-specific safety plans

- Equipment inspection protocols

- Regular safety audits

- Proper PPE investment

- Clear, effective communication channels

- Staying current with OSHA standards

- Maintaining strong subcontractor relationships,

- Implementing digital safety management solutions

SafetyHQ, a construction safety app, makes construction safety management easier. It handles everything from scheduling inspections to managing certifications. It also helps with generating compliance reports and organizing documents for OSHA inspections.

SafetyHQ software solutions help construction companies move beyond basic compliance by analyzing patterns and data. It helps contractors create a more responsive, data-driven safety culture. This improves workplace safety and helps protect companies from costly violations and reduces the risk of accidents.

For more information about how to improve safety processes, talk to an expert here.

Share Article

Keep on current news in the construction industry. Subscribe to free eNews!